EXPERTISE

3 Fields

1 Supplier

Engineering

Our engineering department is staffed by qualified engineers with many years of experience and technical know-how. Since our employees are specialized in different fields, we can offer a wide range of different services. These range from static calculations, resource and economic planning to site management activities on the construction site.

In our work, we always attach great importance to good communication – both internally and with our external business partners. For us, this is a central prerequisite for a successful construction project.

Meet some of our competent employees

Production

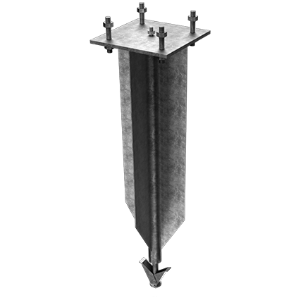

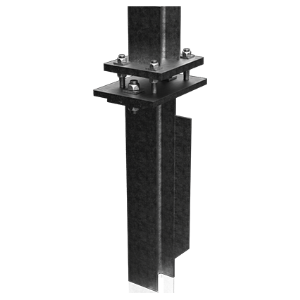

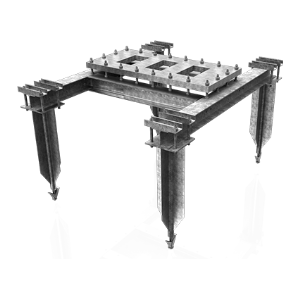

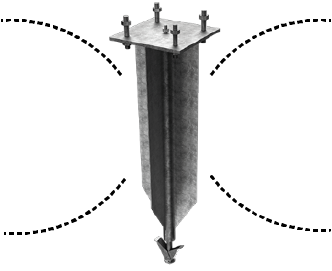

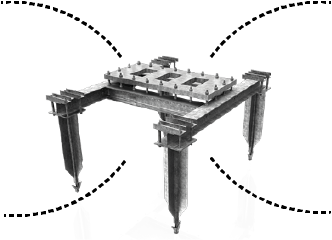

Our unique steel foundations

Installation

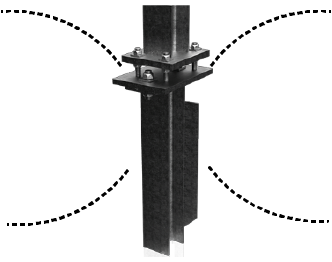

The bolt connection of the

GroundPlug foundations can be adjusted with +/- 70mm in all directions. Thus,

a high precision of +/- 5mm

is achieved.

GroundPlug foundations can installed

in one day without any need for

additional visits on the site.

Through synergy effects, effective management and a time-saving installationprocess, we can always

offer cost-effective solutions

In contrast to concrete, GroundPlug foundations can also be installed in frost and rain. The construction time can thus be reduced significantly.

We deliver everything from planning, production to the installation of various constructions - always with a focus on effectiveness, economy and reliability.

NOISE BARRIER L=200m, H=3m

| STEEL FOUNDATION | CONCRETE FOUNDATION | |

|---|---|---|

| Amount [pcs] | 50 | 40 |

| Weight GroundPlug HE foundation [kg/ pcs] | 150 | n.a. |

| Total weight of GroundPlug HE foundations [kg] | 7518 | n.a. |

| Delivery price of GroundPlug HE foundations [USD] | 19474 | n.a. |

| Concrete amount [m3/ pcs] | n.a. | 0,34 |

| Reinforcement [kg /pcs] | n.a. | 120 |

| Total amount of concrete [m3] | n.a. | 13,6 |

| Total reinforcement [kg/ stk.] | n.a. | 4800 |

| Price concrete material [USD] | n.a. | 11627 |

| Price reinforcement [USD] | n.a. | 7748 |

| Installationtime [days] | 1 | 2 |

| Installation price [USD] | 1857 | 4095 |

| TOTAL PRICE [USD] including installation in 1 day | 21331 | n.a. |

| TOTAL PRICE [USD] including installation in 2 days | n.a. | 23470 |

Interested in our qualifications?

With our profound knowledge in the field of steel constructions we are always pleased to advise you on your upcoming building project.

Contact us at any time – no matter whether you need consulting on a specific project or just want to learn more about our services and expertise.